Stop Losing Money to Bad Quality

Incoming inspection of raw materials, components, and supplies to verify they meet specifications before entering production. Prevents defective materials from compromising final product quality.

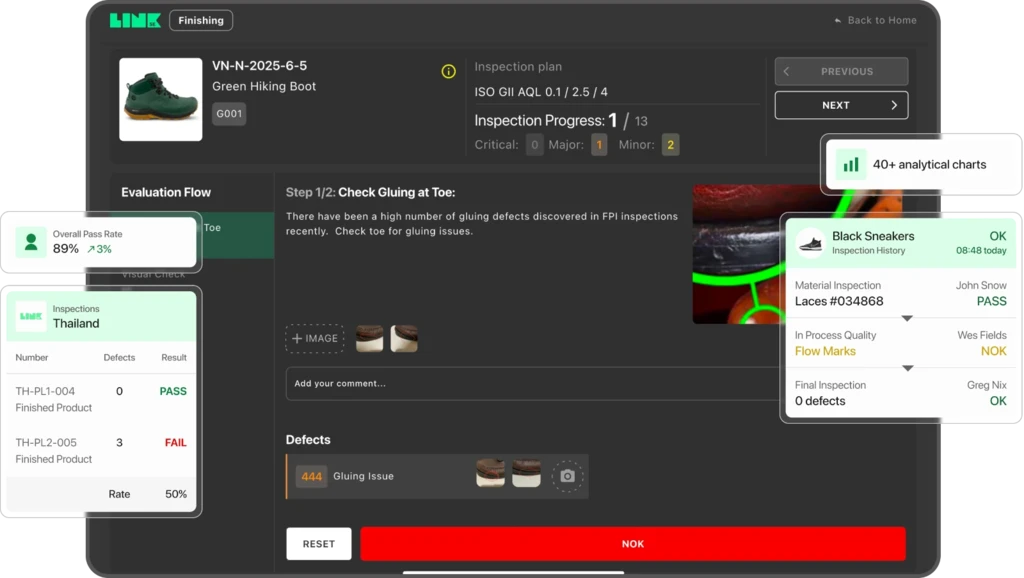

Real-time monitoring and testing during manufacturing to catch defects early, display live data on the shop floor, and ensure consistent quality throughout production stages.

Final inspection and testing of completed products to confirm they meet all quality standards, specifications, and customer requirements before packaging and shipment.

Post-delivery quality monitoring through feedback collection, complaint tracking, and performance analysis to ensure products meet customer expectations and drive continuous improvement.

Explore comprehensive charts with flexible filters to uncover trends and performance.

Get a real-time pulse on production quality. Monitor activity as it happens - no delays, no surprises.

Receive automated email summaries that keep you informed on key quality metrics and trends - stay updated on what matters most.

Manual reporting slows you down. With digital tools for inspections, audits, and maintenance, you get real-time data and clear analytics - so you can spot trends and solve problems fast.

Use the analytics to see and follow individuals' performance to highlight vulnerability. Build training programs to address each individual's specific strengths and weaknesses.