In-process quality control

Catch issues at the key areas of production.

Teams that use Link SE are 31% more productive

13

items evaluated

1.1

defects discovered

Benefits

Eliminate administrative paperwork in production

Reduce quality costs

Increase transparency

Leverage traceability

Minimize rework

Discover defects early

How does it work?

The In-Process Quality Control (IPQC) application system is placed directly into the production line to create detailed layers of quality data. Evaluate WIPs at critical stages of the production to illuminate quality issues and pinpoint focus for action.

1

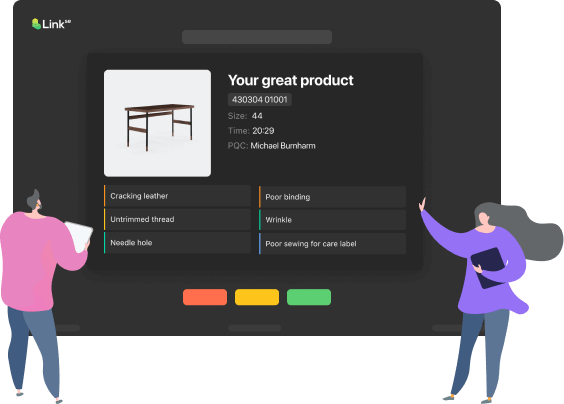

Use desktop application to conduct inspections

Let your customers know what’s hot. Share your latest product, updates and sales events and make sure your customers never miss out on what’s new.

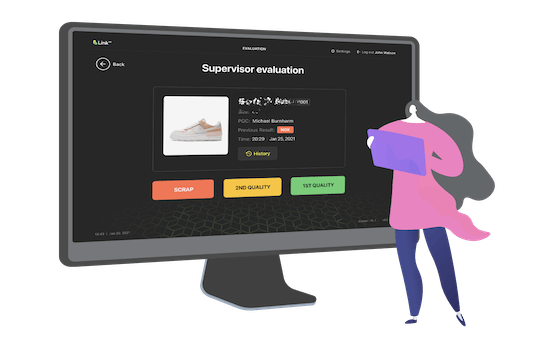

2

Display real-time results on display for shop floor workers to see

Let your customers know what’s hot. Share your latest product, updates and sales events and make sure your customers never miss out on what’s new.

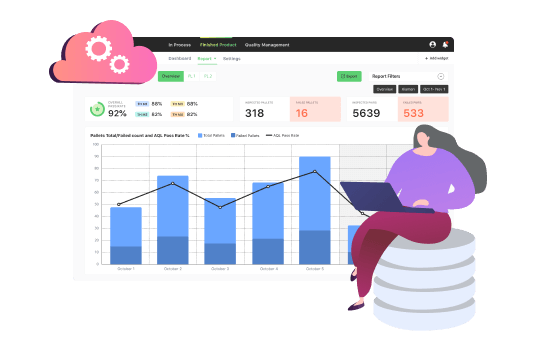

3

Store all data to analyze via web application

Let your customers know what’s hot. Share your latest product, updates and sales events and make sure your customers never miss out on what’s new.

Have a question?

Customer support is our highest priority. We're here to answer all your questions in a timely manner.