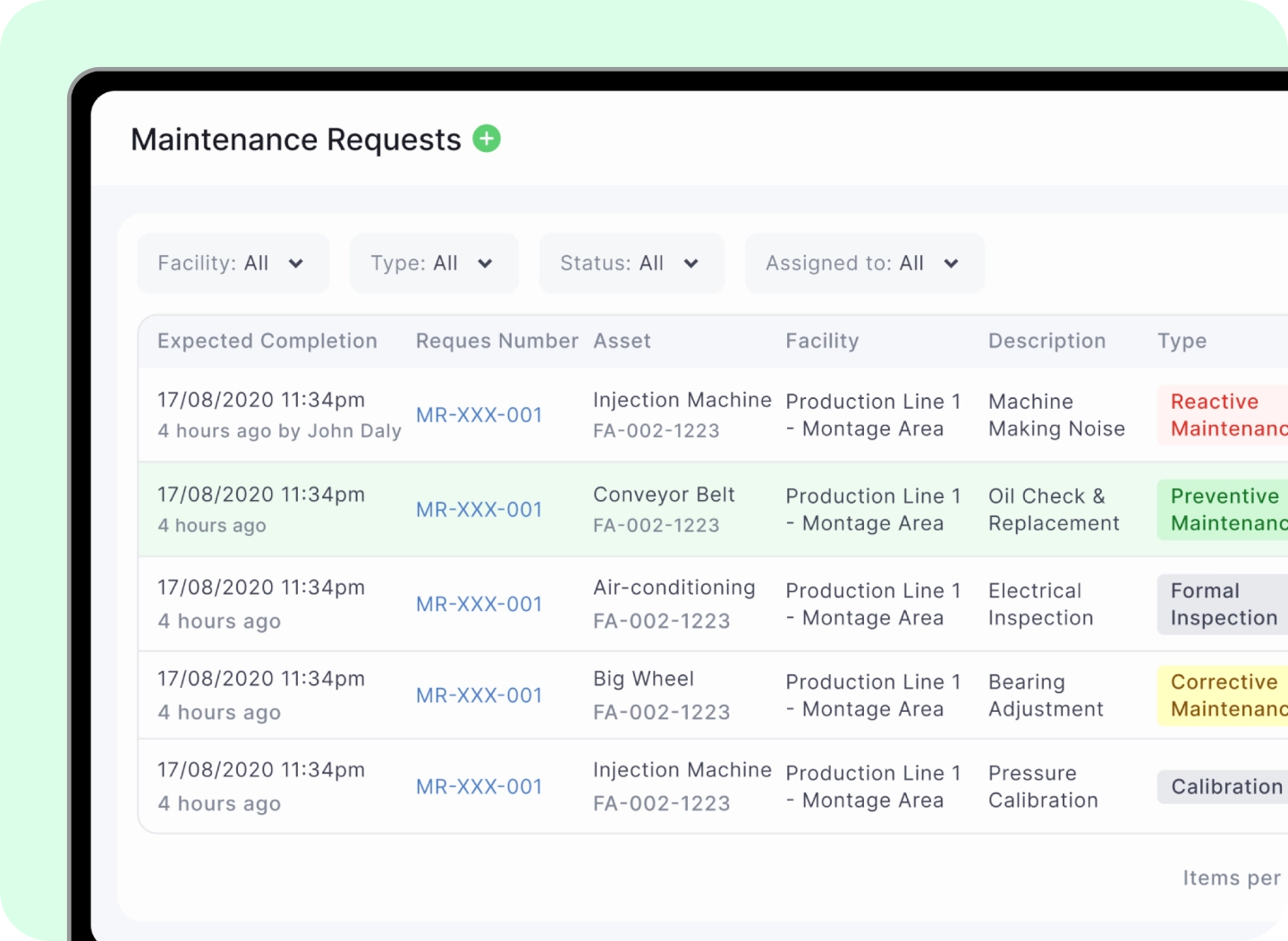

Transform Your Maintenance Operations from Reactive to Predictive

Transform from reactive fire-fighting to proactive maintenance planning. Our intelligent scheduling system supports critical equipment attention before problems occur, reducing emergency repairs and keeping your production lines running smoothly.

Track every piece of equipment from installation to retirement with comprehensive asset management. Monitor performance trends, maintenance history, and lifecycle costs to make informed decisions about repairs, replacements, and capital investments.

Never be out of critical components or tie up capital in excess inventory. Our integrated spare parts management optimizes stock levels based on usage patterns, lead times, and equipment criticality, ensuring parts are available when needed.

Empower your maintenance teams with mobile tools that work on the factory floor. Create work orders, update statuses, capture photos, and access technical documentation anywhere, ensuring nothing falls through the cracks.

Keep critical manufacturing equipment running with scheduled maintenance, rapid response to breakdowns, and comprehensive performance tracking.

Maintain HVAC, electrical, plumbing, and building systems with preventive care that ensures optimal working conditions and regulatory compliance.

Ensure measurement accuracy and compliance with calibration schedules, maintenance records, and performance verification.

Maintain fire suppression, emergency lighting, and safety equipment with regulatory compliance tracking and mandatory inspection schedules.

Link maintenance activities to quality inspections, ensuring equipment condition directly supports product quality. Track how maintenance timing affects quality metrics and optimize schedules for both reliability and quality outcomes.

Maintain comprehensive maintenance records that satisfy audit requirements. Connect maintenance documentation to compliance audits and regulatory inspections with complete traceability and accountability.