DIGITAL QUALITY CONTROL

Quality Inspections Made Easy

Focus on product quality. Give your QCs a powerful tool for recording product inspections and give managers a comprehensive trend analytics tool. Make sure your quality standards are always followed.

Traceability

Create item history from linked material, component, and product inspections.

Easy Configuration

Update QC standards with just clicks. Add new processes in minutes.

Rest API

Collect Product or Order data from your API. Set up with no-code configuration.

Transparency and Visibility

Benefit from real time data collection and report availability.

Escalate Issues Automatically

Inform stakeholders faster to make decisions sooner.

Trend Analysis

Use well structured and comprehensive data to analyze trends over time.

How Does It Work?

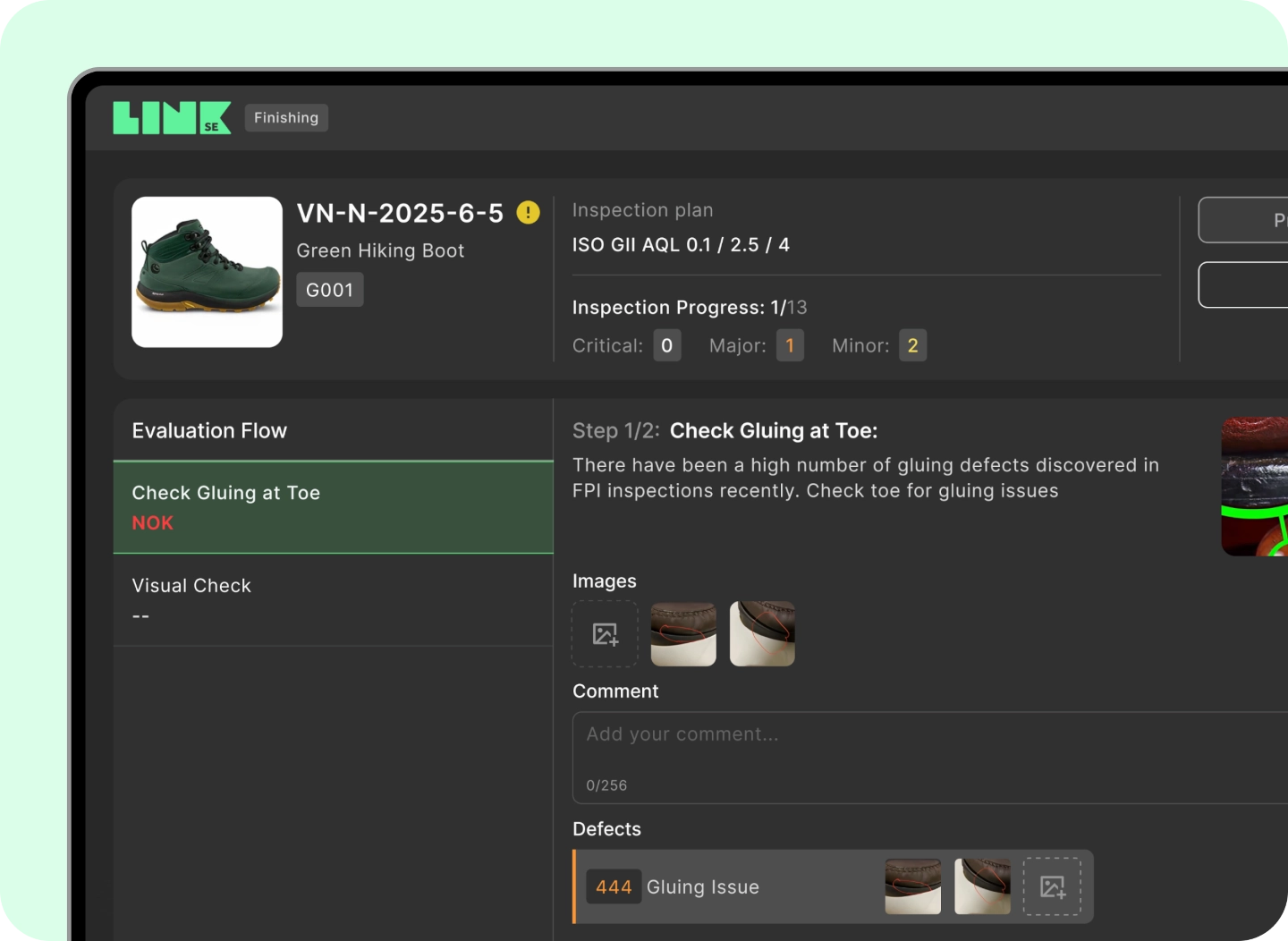

Conduct Inspections via Quality Terminal Application

Download the Quality Terminal application onto your mobile device or desktop station. Use this application to input the inspection results, notes, and to collect data about the batch.

Display Real-Time Results for Shop Floor Workers to See

Utilize TV screens on the shop floor to display real-time inspection results. Download the Visual Spot application on your mobile or computer to check on quality results on the go.

Review Reports and Historical Data on the Web Application

The Web Portal is the home for the more detailed, long term data analysis. Download inspection reports or view inspection results over time with powerful filtering capabilities.

Inspect Any Product or Material

Create effective QC checklists using three flexible data collection methods to guide Quality Inspectors to record defects, measurement values, and key quality issues.

Visual Checks

Check item for visual defects and record the discovered defects supported by images and comments.

Measurements

Measure key product attributes against a defined acceptable tolerance range.

Critical Checks

Highlight specific problem areas to ensure the inspectors check every time.

Analytics

Unleash the Power of Smarter Quality Insights

Web Reports

Explore comprehensive charts with flexible filters to uncover trends and performance.

Live Data Feed

Get a real-time pulse on production quality. Monitor activity as it happens - no delays, no surprises.

Email Digests

Receive automated email summaries that keep you informed on key quality metrics and trends - stay updated on what matters most.

Instant Insights

Trustworthy Data When You Need It

Manual reporting is slow and work intensive - stop wasting resources! Get real time reports and detailed analytics about your products, defects, orders, customers and more. Act swiftly when problems occur.

Quality Analytics

More Than PDFs and Storage

Comprehensive analytics on the Quality data. Drill down on specific customers, orders, defects, QCs, shifts, or production lines. See trends and drive improvement.

Inspection Planner

Plan Inspections and Resources

Create inspection requests to build inspection schedules for orders. Plan and monitor quality inspector workloads inspection request calendar view.

Orders

Link Orders to Inspections

Link orders to inspections to create batch level traceability of your products. Orders also have links to supplier or customer to allow for easy performance review.

65+ Million Products Inspected

Helping our customers to discover 6+ million defects.

Smart Alerts

Automatic Escalations

Set up automatic quality alerts that inform you about bad quality situations based on configurable logic. Eliminate delays in communication and reduce rework with real time information distribution from shop floor to management.

Live QC Board

Shop-floor Reporting

Present real-time quality data to your production teams right on the shop floor and allow them to react on the problems as they happen.

Make the Most of Team Resources

Train Smarter

Use the analytics to see and follow inspector performance to highlight vulnerability. Build training programs to address each inspector's specific strengths and weaknesses.

Trace Issues to the Source

Use In-Process Quality Control and Finished Product Inspection to cover the entire production process to build product traceability. Link SE provides data to find the root cause and contain the damage effectively.

Have a Question?

Customer support is our highest priority. We're here to answer all your questions in a timely manner.